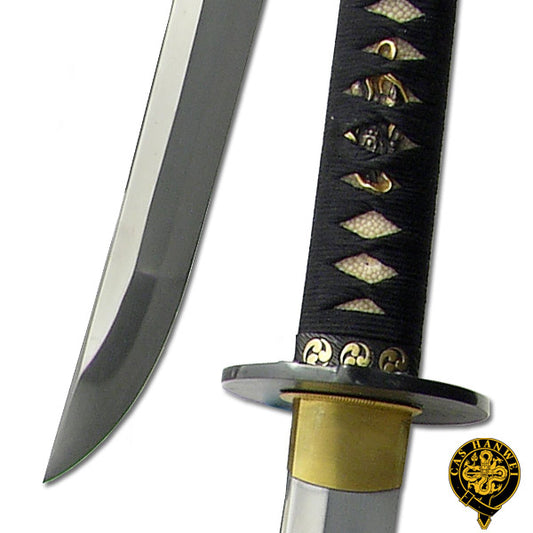

Collection: Hanwei Swords at RVA Katana

The Paul Chen / Hanwei Forge produce some of the finest quality reproduction swords and accessories to the collector and practitioner communities. You will be hard pressed to find a better combination of quality, performance, design and value than the swords that are hand crafted at the Hanwei forge.

How Hanwei makes their sword blades

Hand Forged

With few exceptions Hanwei's blades are hand forged high carbon steel. Coal fired forges heat the blades to just the right temperature and skilled smiths go to work shaping the basic blade profile and shape.

Hand Ground

The forged blades are then ground, by hand, to near their final shape. Any inconsistencies in the swords overall shape or distal taper is corrected and the balance adjusted. The sword is now ready for heat treatment.

Hand Finished

After careful heat treatment (hardening and tempering) in either Hanwei's digitally controlled ovens or salt baths as needed the blades are either polished on the grinder or hand polished in the case of the higher end swords. Once complete the blades are now ready to be precision fit to the hilt pieces.

How Hanwei produces their own fittings - in house

In-house design

Hanwei is one of the only sword makers that produces all of their fittings (handle and scabbard components) in house. From design to production the entire process is handled at Hanwei, ensuring a high level of design, fit and finish. The fittings begin life as hand engraved wax, from those a precision mold is made to copy the original in every way.

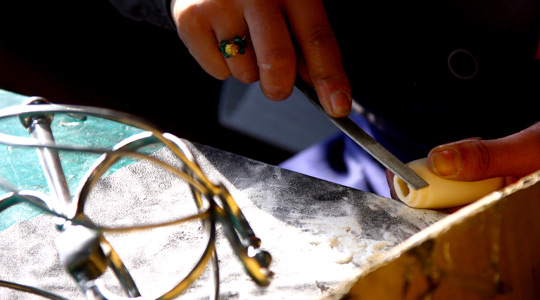

Lost Wax Casting

The precision molds are used to make positive wax copies of the originals, these are coated in a special sand mix in a multi-step process. The hardened sand casings are heated to melt the wax positives leaving a cavity ready for molten steel.

Hand Fitting

The solid steel and sand casings are broken apart, leaving a lot of clean-up work to prepare the part for fitting. Once the completed blade meets the fitting for the first time, each piece is hand adjusted as needed to ensure a proper fit and long life.

-

Dragon King Zatoichi Forged Shikomizue Stick Sword

Regular price $300.00 USDRegular priceUnit price / per$329.00 USDSale price $300.00 USDSale -

Dark Sentinel - Hanwei

Regular price $150.00 USDRegular priceUnit price / per$179.00 USDSale price $150.00 USDSale -

Sold out

Sold outHanwei Stick Sword - Zatoichi

Regular price $225.00 USDRegular priceUnit price / per$259.00 USDSale price $225.00 USDSold out -

Hanwei Paul Chen Practical Plus XL Katana

Regular price $450.00 USDRegular priceUnit price / per$579.00 USDSale price $450.00 USDSale -

CONSIGNMENT Hanwei Katana - Wind and Thunder

Regular price $750.00 USDRegular priceUnit price / per$1,050.00 USDSale price $750.00 USDSale -

Gladius - Legacy Arms v2

Regular price $270.00 USDRegular priceUnit price / per -

Side Sword - Kingston Arms

Regular price $350.00 USDRegular priceUnit price / per$419.00 USDSale price $350.00 USDSale -

Hanwei Paul Chen Raimie XL Katana

Regular price $350.00 USDRegular priceUnit price / per -

Bastard Sword - Hanwei/Tinker

Regular price $300.00 USDRegular priceUnit price / per$369.00 USDSale price $300.00 USDSale -

Claymore - Kingston Arms

Regular price $350.00 USDRegular priceUnit price / per$399.00 USDSale price $350.00 USDSale -

Legacy Arms Roman Maintz Gladius Sword V2

Regular price $270.00 USDRegular priceUnit price / per -

Spada da Lato Side Sword - Kingston Arms

Regular price $350.00 USDRegular priceUnit price / per$439.00 USDSale price $350.00 USDSale -

Sale

SaleHanwei Dadao

Regular price $175.00 USDRegular priceUnit price / per$229.00 USDSale price $175.00 USDSale -

Sale

SaleLegacy Arms Falcata

Regular price $225.00 USDRegular priceUnit price / per$255.00 USDSale price $225.00 USDSale -

Bastard Sword, antique finish - Kingston Arms

Regular price $400.00 USDRegular priceUnit price / per$369.00 USDSale price $400.00 USD -

Kingston Arms Great Sword

Regular price $425.00 USDRegular priceUnit price / per$499.00 USDSale price $425.00 USDSale